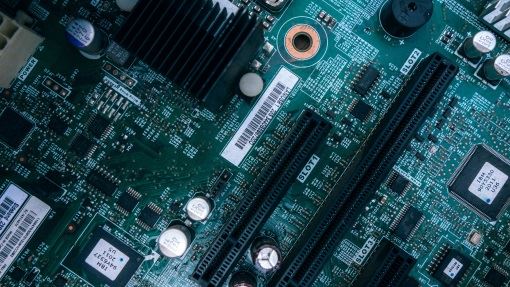

Electronics Manufacturing

A powerful and feature-packed solution designed in Australia for the electronics manufacturing industry

Electronics Manufacturing Software

If your business needs electronics manufacturing software, you need a program that was developed to handle the intricate nature of the business itself in regards to the management of small parts, manufacturing and financial control.

Accentis Enterprise was designed with attention to detail to provide a state-of-the-art ERP software solution that includes a robust MRP manufacturing system, with all other financial and business modules fully-integrated to complete the business needs.

Electronics Manufacturing ERP

Accentis Enterprise had its inception within one of Queensland’s top privately-owned microelectronics manufacturing companies. Mass Electronics is a leader in the design and manufacture of analogue and digital environmental control and measurement equipment.

Like many companies, as Mass Electronics grew and enjoyed a high degree of commercial success it became increasingly burdened by an inadequate and disparate collection of software programs to run its business. Our mission was to produce a world-class, multi-user, fully-integrated enterprise management solution.

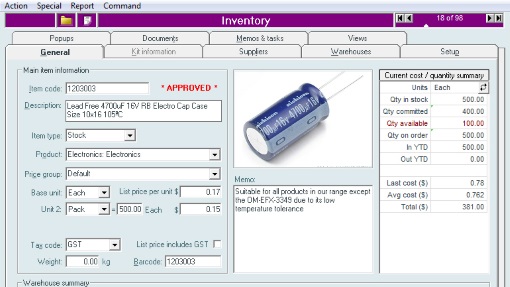

Powerful Inventory

With the large quantity of different components and materials used in the electronics manufacturing, it is imperative that inventory management is efficient, comprehensive and easy to use. Accentis Enterprise supports an unlimited number of different inventory parts including kit items having unlimited levels of sub-assemblies (BOM). It is not uncommon for Accentis customers to maintain over 50,000 part codes – any of which can be accessed or analysed with lightening speed.

Product Approvals

Accentis Enterprise helps you maintain a record of product approvals for your own products that you manufacture as well as your raw materials. For local and international standards such as UL, CE, C-Tick or even ROHS compliance, you can easily track the standard to which products conform and only select appropriate raw materials for building certain products. Any products that have been approved within Accentis Enterprise cannot be modified in any way without special administrative permissions.

Version Management

The single most important feature in a good manufacturing system is the ability to record and manage multiple versions of kits (Bill of Materials). Accentis Enterprise is the leader in this area and supports full version management on every assembly with the ability to build any specified versions of a product. Any change to an assembly’s bill of materials is tracked and stamped with either a user-defined or auto-assigned version number, while a free-text notation indicating why the change was made can also be added.

Advanced Purchasing

Support for unlimited number of suppliers per part, with each supplier assigned a relative ranking from most least preferred. Each supplier for a part can store the supplier’s part code and description so that purchase orders can be printed using the supplier’s own codes, saving precious time when ordering. Multiple units of measure for each supplier-part combination allow parts to be ordered by any unit (e.g. a reel, roll, box or tube) and a price and quantity conversion factor for each unit to be specified.

Manufacturing Management

The heart of the manufacturing system in Accentis Enterprise is the Work order which is created to build a specified quantity of an assembly from raw materials or sub-assemblies.

- Partial builds allow you to start building without components in stock

- Flexible modification of Bill of materials during Work Order stage

- Complete repairs facility to record issues and prevent future problems

- Schedule control of employees displays who is working on what job

- BoM requirements with advanced date management functionality

- Track multiple work orders through each stage of progress

Micro Electronics Inventory Control

Accentis Enterprise provides a functional, but well-advanced solution to counter any issues and keep Inventory management under complete control. A robust warehousing, distribution and supply chain management (SCM) solution for your SMB to grow into the future with.

You can easily maintain multiple warehouses throughout the business to reflect not only physical locations, but allows for the creation of virtual warehouses for component collections. These could be delegated as raw materials warehouse, production warehouse, quarantine warehouse and finished products or sales warehouse.

Download The Accentis Enterprise Brochure Now

Download the Accentis Enterprise brochure and see what small business owners are doing to improve their business. Accentis Enterprise is the solution that every SMB/SME needs to stay ahead of the pack!

Electronics, microelectronics and controls features

Accentis Enterprise Features for Electronics Manufacturers

Accounting & Financials

Your customer’s financial accounts can be split into multiple databases if needed for different business ventures. Support for no end of month roll-overs allowing you to edit past transactions.

Customer Sales & CRM

Record every transaction from each customer, whether a wholesale or retail, or a one-off or a regular supply. Build new relationships with other factories, market competitors, customers and more!

Asset & Maintenance

Easily identify manufacturing machinery through photos stored against each record for better evaluation. Monitor and manage asset warranties and information through heavy reporting and analysis.

Suppliers & Purchasing

An in-built Supply Chain Management (SCM) facility provides comprehensive shipping and ordering features that will give you the edge over competitors supplying to the same vendor.

Inventory & Warehousing

Track and manage thousands of raw materials and product purchases across multiple locations and departments. Instantly view a report on your current order production value through stock.

Time & Attendance

Record employee time spent setting up builds or packing supplies. Allowances for time spent working on projects are recorded and can be used to work out the true value of items you produce.

Payroll with STP & HR

Manage all factory employees including holidays and time worked with our Payroll & HR module, that is fully Single Touch Payroll compliant for small to medium-sized businesses.

Jobbing & Project Management

Continual projects and one-off jobs can be allocated staff time and budgets for overall budget management. Seamless integration with both Payroll and Time Clock give instant accountability.

Manufacturing MRP & Producing

Exceptional manufacturing with MRP support, so management of each step requires data retention, staff allocation and product history. Accentis Enterprise helps your business power others.

AccentisCONNECT

Your chance to connect and view data with ease, direct from your own database! Powerful web-service gateway for third-party solutions to read/write the data you need.

Want More?

Click here to get more information and see how you can start to beat your competition through better a business management solution!

Reporting & Analysis

Over 800 standard reports available ready to manage your each process and all the data you produce, plus… Accentis Enterprise offers advanced custom reports as needed!

Electronic

Manufacturers

Who Use

Accentis Enterprise

Our customers push us to deliver powerful features and advanced functionality that are used by the people who need them.

By delivering on our promises, we’ll improve your efficiency, streamline your processes and help your business grow to the next level and beyond.